For Commercial & Residential Properties

SERVICES

Coatings

Inspections & Free Quotes

Repairs & Restorations

Removal

Skylights

Certifications

Wall Foam Insulation

New Construction Services

ROOF TYPES

Pitched

Flat

Modified

Tile

Foam

Shake

Shingle

Solar

Schedule Roof Inspection

An effective way to determine a solution for a roofing problem is to work with a trained VRS inspector.

This can be achieved by scheduling an inspection appointment and communicating with our team.

Visit the inspection page by using the button below and share some high-level info about your property.

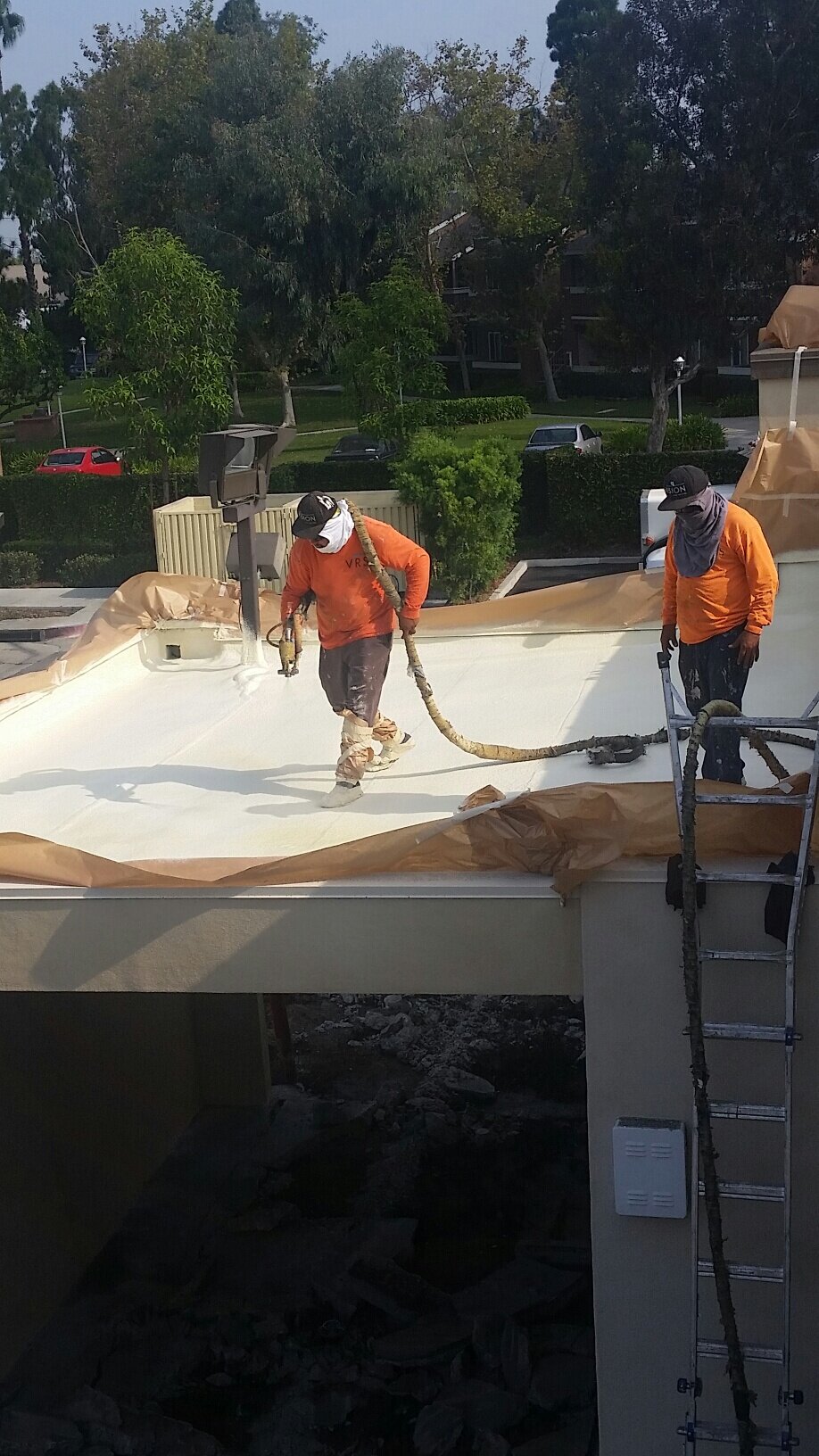

Understanding Our Unique Foam Roofing Service

Polyurethane Spray Foam

About

Spray foam insulation, also known as foaming insulation or sprayed insulation, is a two-part liquid insulation material that insulates and air seals wherever it is applied. The material comes in two large 55 gallon drums – an iso and a resin. These two liquids are kept separate until applied at the jobsite by a qualified, licensed spray foam installer. The two liquids travel up through a heated hose to the spray gun where they are combined to create the foam. The foam expands within seconds to fill the cavity surface. Depending on the type of sprayed-in foam insulation used, closed-cell or open-cell, the foam expands between 40 and 100 times its size upon application.

Types

Open-cell sprayed-in foam insulation, a soft low-density material, is typically used for interior applications such as wall cavities, underside of roof decks, attics, basement walls and crawlspaces. The open cell structure of low density foamed insulation allows for moisture permeability to help contribute to moisture management and bi-directional drying of the wall assembly.

Closed-cell spray insulation, a rigid medium-density material, can be used in exterior applications such as continuous insulation applications, as well as interior applications. This type of foam insulation has a higher R-value per inch making it also suitable for small areas that require the highest possible R-value to meet building code requirements. Closed-cell spray foam’s rigidity help reject bulk water making it a recognized flood-resistant material by FEMA.

Benefits

Open-cell (best suited for interior applications)

Allows for bi-directional drying

Can accommodate long-term creep and seasonal movement

Can be installed at a significantly lower cost and target the same specified R-value

Is not considered a food source for mold

Provides sound dampening qualities, ideal for use media or theater rooms

Lower installed cost, per square foot

Closed-cell

Ability to reject bulk water (closed-cell foam insulation is recognized as a flood resistant material by FEMA)

Can be applied at very low temperatures (as low as 5°F)

Adds wall racking strength as well as impact resistance

Higher R-value per inch – easier to accommodate high R-value requirements in narrow spaces

Lower vapor permeance (can be a Class II VDR)

Higher tensile and bond strength

New Construction Services

Preconstruction planning (consulting services for residential and commercial)

Safety and compliance advisory services

Roofing material sourcing and cost strategy

New residential roof implementation (single home, apartments, communities)

New commercial roof build out (foam, solar, traditional materials)

Post-construction checks and maintenance

Gallery

Interested in seeing more of our work?

Visit our Featured Projects page for specific, challenging jobs we’ve completed.

Have a question?

Get in touch by visiting the Connect form.